Agricultural and Biological Research

RNI # 24/103/2012-R1

Research Article - (2024) Volume 40, Issue 1

Canals are the major conveyance system of any irrigation project, delivering irrigation water to fields. Irrigation schemes include an extensive distribution system which is an expensive proposition. So, it is necessary to ensure that large water losses do not occur due to seepage. Most of these canals are earthen so considerable water losses occur due to seepage. In most of the earthen canals water is lost due to evaporation and seepage. The comparison between empirical formulas and field tests for estimating seepage losses in the Hajira Branch Canal offers valuable insights into the accuracy and reliability of different estimation methods. While empirical formulas provide a quick and accessible means of estimation, the findings from field tests underscore the importance of on-site measurements and real-time data collection for more precise assessments. However, evaporation losses are not more significant in most of the cases. Seepage loss is the prime factor in water loss in most of the earthen unlined canals. In the present study, a hajira branch canal is taken in consideration to determine seepage losses. These losses are computed by using Davis and Wilson formula, Molesworth and yennidunia empirical and analytical formula, Pakistani formula, Nazir ahmad formula and Mortiz formula, which are compared with field test results.

Canal; Seepage; Particle size distribution; Empirical formula; Irrigation

Canals are considered as one of the significant conveyance system of any irrigation project [1]. A canal may be of rigid boundary or mobile boundary canal [2]. Compare to the lined or rigid boundary canal, an unlined canal is subjected to a significant water loss due to the seepage [2]. Seepage can be defined as the movement of the water in or out from the voids present in the bed and sides of the earthen unlined canal [3]. Due to the seepage, more than 50% of usable water is get lost [1]. Seepage loss also causes depletion in freshwater resources, water logging, salinization, and ground water contamination [2]. Therefore, it is essential to determine seepage losses to reduce the amount of water loss and to serve the maximum command area. Most of the canals are earthen canal which is inexpensive to construct but it loses 50 percent or more water due to seepage. These type of canals are more liable to get eroded due to weed growth and other problems which gently reducing the effectiveness of over the time. In old earthen irrigation canals in considerable water loss is take place due to seepage from its sides & bed which results into low conveyance efficiency of canal. Earthen canals are also get clogged due to weed growth which reduces its water carrying capacity. In the present study, Hazira branch canal is taken in the consideration. Seepage losses are determined by indirect method (Particle size distribution), and also by empirical formulas.

Need of study

1. Seepage from irrigation canals results in waterlogging of valuable agricultural land and also makes land excessive alkaline. So, it constitutes a serious agricultural problem.

2. Insufficient maintenance, problem of leakages and seepages is also present in command area resulting in wastage of water, water logging etc.

3. Seepage rates in earthen canals are very high as 45%, so if these rates are reduced considerable amount of water is save which can be used for irrigating more area.

Study area

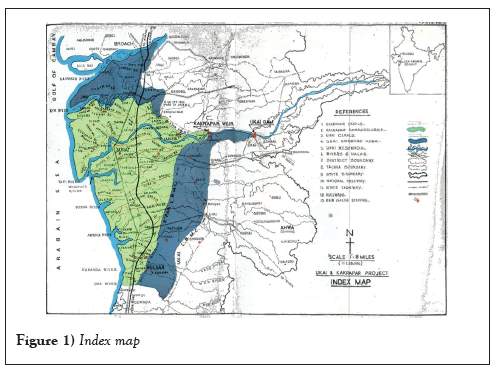

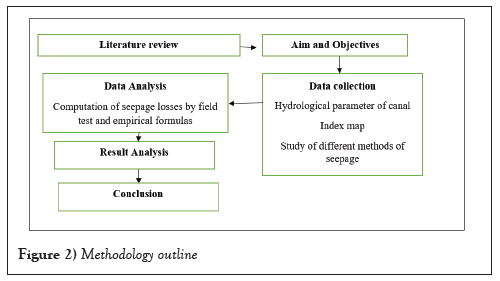

Hajira is known as the industrial hub of the India. It is located in Surat, Gujarat at coordinates of 21.13451°N 72.64772°E. It is 8 kms away from the Arabian Sea. It is having the total area of 168 kms. It is base for major industries and shipping facilities like Essar, Kribhco, Shell, Larsen & Toubro, NTPC, ONGC, GAIL, Gujarat State Petroleum Corporation, UltraTech Cement and Reliance Industries. Hajira Branch Canal was constructed as unlined canals in 1954 and 1975 respectively. Hajira branch canal is taking off from kakarapar right bank main canal having total discharge of 1207 cusecs and having total length of 34 km (Figures 1 and 2 and Table 1).

| Rd | Length (m) | BW (m) | FSD (m) | FB | Peri. (m) | Q (cumec) | Velocity (m/sec) | Area (m²) | N | S | R (m) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 15.6 | 4754.8 | 12.8 | 2.05 | 0.9 | 21.06 | 32.58 | 0.995 | 34.45 | 0.017 | 0.00015 | 1.635802 |

| 24.3 | 7406.64 | 12.5 | 1.85 | 0.9 | 20.03 | 30.89 | 1.08 | 28.78 | 0.017 | 0.00015 | 1.436845 |

| 32 | 9753.6 | 12.3 | 1.85 | 0.9 | 20.03 | 30.28 | 1.08 | 28.78 | 0.017 | 0.00015 | 1.436845 |

| 37.46 | 11417.81 | 12.3 | 1.8 | 0.6 | 19.82 | 30.24 | 1.12 | 28.78 | 0.017 | 0.0002 | 1.452069 |

| 41.16 | 12545.57 | 12.3 | 1.8 | 0.6 | 20.82 | 29.89 | 1.12 | 26.55 | 0.017 | 0.00016 | 1.275216 |

| 46.5 | 14173.2 | 9.75 | 1.8 | 0.6 | 16.92 | 24.97 | 1.15 | 22.41 | 0.017 | 0.00016 | 1.324468 |

| 48.41 | 14755.36 | 9.4 | 1.8 | 0.6 | 16.92 | 24.75 | 1.14 | 21.78 | 0.017 | 0.00016 | 1.287234 |

| 50.136 | 15281.45 | 8.6 | 1.8 | 0.6 | 16.92 | 24.75 | 1.14 | 21.78 | 0.017 | 0.00016 | 1.287234 |

| 52 | 15849.6 | 8.6 | 1.8 | 0.6 | 16.92 | 24.72 | 1.14 | 21.78 | 0.017 | 0.00025 | 1.287234 |

| 54.2 | 16520.16 | 8.6 | 1.8 | 0.6 | 16.92 | 24.72 | 0.8 | 21.78 | 0.017 | 0.00025 | 1.287234 |

| 57.375 | 17487.9 | 8.6 | 1.8 | 0.6 | 16.12 | 24.65 | 0.8 | 21.78 | 0.017 | 0.00025 | 1.351117 |

| 66.85 | 20375.88 | 8.6 | 1.8 | 0.6 | 17.12 | 22.69 | 0.8 | 15.08 | 0.017 | 0.00025 | 0.880841 |

| 71.825 | 21770.34 | 6.3 | 1.65 | 0.6 | 18.12 | 21.55 | 0.73 | 12.24 | 0.017 | 0.00025 | 0.675497 |

| 74.5 | 22707.6 | 6.3 | 1.65 | 0.6 | 13.19 | 21.4 | 0.73 | 12.24 | 0.017 | 0.00025 | 0.927976 |

| 77.425 | 23599.14 | 6.3 | 1.65 | 0.6 | 13.19 | 20.98 | 0.73 | 12.24 | 0.017 | 0.00025 | 0.927976 |

| 79.856 | 24079.2 | 6.3 | 1.65 | 0.6 | 13.19 | 20.55 | 0.73 | 12.24 | 0.017 | 0.00025 | 0.927976 |

| 80.86 | 24646.12 | 6.3 | 1.3 | 0.6 | 11.73 | 20.43 | 0.65 | 12.2 | 0.017 | 0.00025 | 1.040068 |

| 82.2 | 25054.56 | 6 | 1.3 | 0.6 | 15.12 | 20.15 | 0.65 | 12.24 | 0.017 | 0.00025 | 0.809524 |

| 85.5 | 26060.4 | 6 | 1.3 | 0.6 | 14.15 | 19.95 | 0.65 | 12.23 | 0.017 | 0.000352 | 0.864311 |

| 87.554 | 26686.4 | 6 | 1.3 | 0.6 | 14.73 | 19.8 | 0.61 | 12.2 | 0.017 | 0.000352 | 0.828242 |

Table 1: General details (Dimensions and characteristics of different sections).

Figure 1: Index map.

Figure 2: Methodology outline.

Estimation of seepage losses

Seepage from an irrigation canal is usually measured by following methods.

1) Direct measurement method

2) Indirect measurement method

Direct measurement method

Seepage from an irrigation canal is usually measured by direct measurement methods:

I. Ponding test.

II. Inflow-outflow method

III. Seepage meter method

IV. Constant and variable head parameters

Direct method cannot be used as prevailing site condition and does not permit the same and hence, it is decided that the indirect method of finding the seepage by conducting the seepage analysis of the soil in the laboratory was performed.

Indirect measurement method

Grain size analysis (Sieve analysis): The soil samples are taken for grain size distribution by mechanical analysis in the laboratory. The samples are oven dried first then perform experiment and find out the percentage finer of the soil and distribute the soil by grade sizes by Wentworth scale.

Sieve analysis

1. Write down the weight of each sieve as well as the bottom pan to be used in the analysis.

2. Record the weight of the given dry soil sample.

3. Make sure that all the sieves are clean, and assemble them in the ascending order of sieve numbers (4.75 mm sieve at top and 75-micron sieve at bottom).

4. Place the pan below 75-micron sieve. Carefully pour the soil sample into the top sieve and place the cap over it.

5. Place the sieve stack in the mechanical shaker and shake for 10 minutes.

6. Remove the stack from the shaker and carefully weigh and record the weight of each sieve with its retained soil. In addition, remember to weigh and record the weight of the bottom pan with its retained fine soil.

Estimation from grain size

Allen Hazen derived an empirical formula for approximating hydraulic conductivity from grain size analysis:

K = C(D10)2

Where,

Hazen's empirical coefficient, which takes a value between 0.0 and 1.5 with an average value of 1.0. A.F. Salarashayeri and M. Siosemarde give C as usually taken between 1.0 and 1.5, with D in mm and K in cm/s.

D10 is the diameter of the 10 percentile grain size of the material.

By using earthen dam seepage line concept seepage rate is found by using Q=KS.

General values of permeability for different soils are given in Table 2.

| Type of soil | Value |

|---|---|

| Gravel | Greater than 10-2 m/sec |

| Sand | 10-6 m/sec to 10-2 m/sec |

| Silt | 10-9 m/sec to 10-4 m/sec |

| Clay | 10-11 m/sec to 10-8 m/sec |

Table 2: General values of permeability.

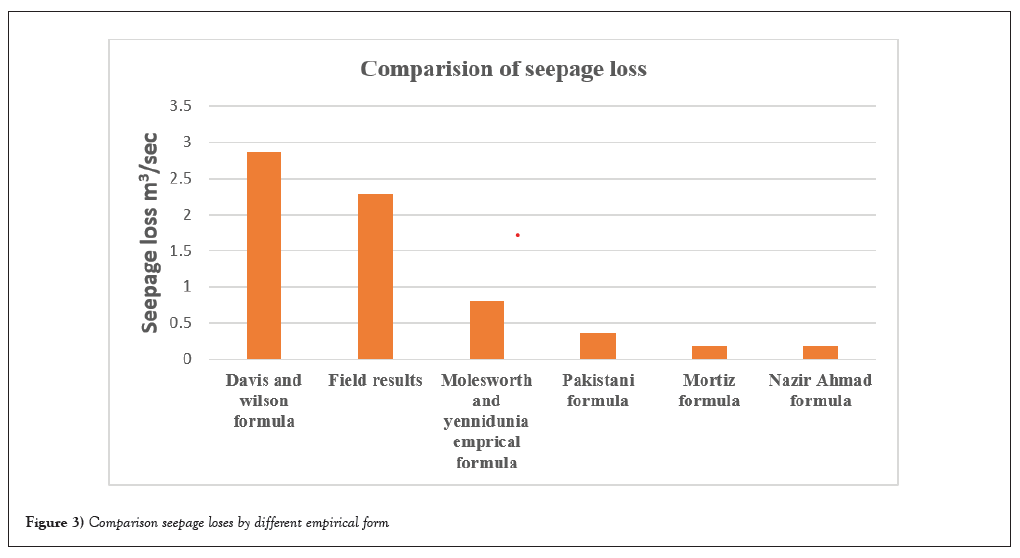

In the present study, a total of 20 sections of the Hajira branch canal are taken into consideration, starting from Rd. 15.6 to Rd. 87.554. From all the sections, soil samples were collected, and sieve analysis has been performed. The field test results of the seepage loss from the Hajira branch canal are shown in Table 1. By using the indirect measurement method, which is grain size analysis, hydraulic conductivity has been found. Afterwards, seepage losses are calculated using the Allen hazen empirical formula [4]. This value is obtained as 7.5 E-05 cum/m length (Table 3). The amount of water lost due to the seepage in Hajira branch canal in the hot season and all seasons has been shown in Tables 4 and 5, respectively. In the hot season, a total of 80 days were considered when the canal was in operation. From the calculation, the yearly seepage loss comes to around 15828480 m³/year. In terms of monetary value, considering the cost of 2.37 rupees/cumec, it is 3.75 crores. Similarly, the amount of water lost due to the seepage in all seasons comes around 43528320 m³/year, which is around 10.31 crores by considering 2.37 rupees/cumec. Table 6 shows the results of the computed average seepage losses for Hajira branch canal at different critical sections by the Davis and Wilson formula [5], Molesworth and yennidunia formula [6], Pakistani formula [7], Mortiz [8], Nazir Ahmad formula [9], and field results. The seepage losses by Davis and Wilson [5], Field test, Molesworth and yennidunia [6], Pakistani [7], Mortiz [8] and Nazir Ahmad formula [9] are 0.143694573 m³/s, 0.1144355 m³/s 0.04051233 m³/s, 0.017497216 m³/s, 0.008737758 m³/s, and 0.00872696 m³/s respectively. Moreover, comparative analysis has been done to find accurate results for the seepage loss. From the graph, it is visible that the Davis and Wilson and particle size methods gave applicable results when compared with the different actual measurements [10-12] (Figure 3 and Table 7).

| Nazir Ahmad formula [9] |  |

S=Seepage losses in m³/s/km length of canal. Q=Channel Discharge in m³/s |

| Mortiz Formula [8] |  |

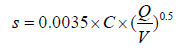

S=Seepage losses in m³/s/km length of canal Q=discharge m³/s V=Mean velocity m/s C=Constant value depending on soil type 0.34 for clay and 2.2 for sand soil. |

| Pakistani Formula [7] |  |

S=Seepage losses in feet3/s Q=Discharge in feet3/s P=Wetted perimeter of wetted section in m. L=Length of channel in feet. |

| Molesworth and Yennidunia Emprical formula [6] |  |

S=Conveyance losses for a given canal length m³/s L=Canal length in km P=Wetted perimeter in m R=Hydraulic radius in m C=Factor depends on soil types, for clay 0.0015 and for sand 0.003 |

| Davis and wilson formula [5] |  |

S=Seepage, in m³/sec/m² of wetted surface of the canal, h=Water depth, in meters, V=Flow velocity in the canal, in m/s, C=Numerical coefficient=3.5 |

Table 3: Determination of seepage losses by empirical formula.

| S. No. | Rd | D10 in mm | K (m/sec) | S (m) | Seepage rate (cumecs/m length) | Length (m) | Seepage rate (m³/sec) |

|---|---|---|---|---|---|---|---|

| 1 | 15.6 | 0.15 | 0.000225 | 0.16 | 0.000072 | 4754.8 | 0.342346 |

| 2 | 24.3 | 0.16 | 0.000256 | 0.14 | 7.17E-05 | 2651.84 | 0.190084 |

| 3 | 32 | 0.2 | 0.0004 | 0.14 | 0.000112 | 2346.96 | 0.26286 |

| 4 | 37.46 | 0.16 | 0.000256 | 0.14 | 7.17E-05 | 1664.208 | 0.11929 |

| 5 | 41.16 | 0.19 | 0.000361 | 0.14 | 0.000101 | 1127.762 | 0.113994 |

| 6 | 46.5 | 0.17 | 0.000289 | 0.14 | 8.09E-05 | 1627.63 | 0.131708 |

| 7 | 48.41 | 0.16 | 0.000256 | 0.14 | 7.17E-05 | 582.16 | 0.041729 |

| 8 | 50.136 | 0.15 | 0.000225 | 0.14 | 0.000063 | 526.09 | 0.033144 |

| 9 | 52 | 0.12 | 0.000144 | 0.14 | 4.03E-05 | 568.15 | 0.022908 |

| 10 | 54.2 | 0.15 | 0.000225 | 0.14 | 0.000063 | 670.56 | 0.042245 |

| 11 | 57.375 | 0.15 | 0.000225 | 0.14 | 0.000063 | 967.74 | 0.060968 |

| 12 | 66.85 | 0.2 | 0.0004 | 0.14 | 0.000112 | 2887.98 | 0.323454 |

| 13 | 71.825 | 0.3 | 0.0009 | 0.13 | 0.000234 | 1516.38 | 0.354833 |

| 14 | 74.5 | 0.15 | 0.000225 | 0.13 | 5.85E-05 | 815.34 | 0.047697 |

| 15 | 77.425 | 0.16 | 0.000256 | 0.13 | 6.66E-05 | 891.54 | 0.059341 |

| 16 | 79.856 | 0.15 | 0.000225 | 0.13 | 5.85E-05 | 740.97 | 0.043347 |

| 17 | 80.86 | 0.15 | 0.000225 | 0.09 | 4.05E-05 | 306.01 | 0.012393 |

| 18 | 82.2 | 0.2 | 0.0004 | 0.09 | 0.000072 | 408.44 | 0.029408 |

| 19 | 85.5 | 0.15 | 0.000225 | 0.09 | 4.05E-05 | 1005.84 | 0.040737 |

| 20 | 87.554 | 0.12 | 0.000144 | 0.09 | 2.59E-05 | 626 | 0.016226 |

| Average | 0.000293 | 7.59E-05 | 0.114436 | ||||

Table 4: Seepage loss result.

| Total seepage considering canal is running 220 days in year | 43528320 m³/yr |

| Considering Rs. 2.37 per cum of water charges total cost of water loss by seepage in all season | 103162118.4 Rs.10.31 cr |

Table 5: Seepage losses in canal in hot season.

| Total seepage considering canal is running for 80 days | 15828480 m³/yr |

| Considering Rs. 2.37 per cum of water charges total cost of water loss by seepage in hot season | 37513497.6 Rs. 3.75 cr |

Table 6: Seepage losses in canal in all season.

Figure 3: Comparison seepage loses by different empirical form.

| S. No. | Davis and wilson formula (m³/sec) | Field results (m³/sec) | Molesworth and Yennidunia emprical formula (m³/sec) | Pakistani formula (m³/sec) | Mortiz Formula (m³/sec) | Seepage rate by nazir formula (m³/sec) |

|---|---|---|---|---|---|---|

| 1 | 0.950389 | 0.342346 | 0.192109 | 0.073629 | 0.0333298 | 0.035775 |

| 2 | 0.381029 | 0.190084 | 0.095505 | 0.038921 | 0.0173732 | 0.019242 |

| 3 | 0.337222 | 0.26286 | 0.084525 | 0.034401 | 0.0152233 | 0.016801 |

| 4 | 0.224157 | 0.11929 | 0.059621 | 0.024136 | 0.0105932 | 0.011903 |

| 5 | 0.147202 | 0.113994 | 0.039772 | 0.017168 | 0.0071369 | 0.008002 |

| 6 | 0.145728 | 0.131708 | 0.047541 | 0.019901 | 0.0092908 | 0.01022 |

| 7 | 0.050658 | 0.041729 | 0.016763 | 0.007114 | 0.0033229 | 0.003633 |

| 8 | 0.045779 | 0.033144 | 0.015149 | 0.006411 | 0.0030028 | 0.003283 |

| 9 | 0.049439 | 0.022908 | 0.01636 | 0.006924 | 0.0032409 | 0.003543 |

| 10 | 0.058359 | 0.042245 | 0.019309 | 0.008172 | 0.0045662 | 0.004182 |

| 11 | 0.080241 | 0.060968 | 0.0272 | 0.011264 | 0.0065805 | 0.006023 |

| 12 | 0.176081 | 0.323454 | 0.069605 | 0.035507 | 0.0188409 | 0.01699 |

| 13 | 0.072809 | 0.354833 | 0.033874 | 0.019666 | 0.0100927 | 0.008614 |

| 14 | 0.028497 | 0.047697 | 0.01554 | 0.007694 | 0.0054078 | 0.00461 |

| 15 | 0.031161 | 0.059341 | 0.016992 | 0.008402 | 0.0058549 | 0.004973 |

| 16 | 0.025898 | 0.043347 | 0.014122 | 0.006974 | 0.0048159 | 0.004075 |

| 17 | 0.00747 | 0.012393 | 0.005491 | 0.00256 | 0.0021016 | 0.001676 |

| 18 | 0.012894 | 0.029408 | 0.008335 | 0.004401 | 0.0027858 | 0.002217 |

| 19 | 0.029691 | 0.040737 | 0.019848 | 0.010136 | 0.0068262 | 0.005422 |

| 20 | 0.019189 | 0.016226 | 0.012588 | 0.006563 | 0.004369 | 0.003357 |

| Total | 2.873891 | 2.28871 | 0.810247 | 0.349944 | 0.1747552 | 0.174539 |

| Average | 0.143695 | 0.114436 | 0.040512 | 0.017497 | 0.0087378 | 0.008727 |

Table 7: The results of the computed average seepage losses for Hazira canal at different critical sections by various formula.

Seepage losses of Hazira branch Canal were computed by empirical formulas at different sections along the total length of the canal. The study's conclusion emphasizes the need for a balanced approach, leveraging the convenience of empirical formulas while recognizing their limitations in capturing site-specific conditions accurately. Field tests remain pivotal in validating and refining these formulas, enhancing their applicability and ensuring more dependable estimations of seepage losses. The main conclusions can be summarized as follows:

1. The seepage losses are computed by using various empirical and particle size analysis method, from the results it is seen that Davis and Wilson Empirical and particle size analysis method gives good result.

2. We advise using Particle size method and Davis and Wilson Empirical Formula for computing seepage losses in Hazira branch canal.

3. Considering this much seepage losses in the canal, it is advised to provide canal lining in order to cover whole command area for irrigation.

Citation: Mistry KV. Estimation of seepage losses using empirical formulas in comparisons with field test from Hajira Branch Canal. AGBIR.2024;40(1):801-806.

Received: 05-Dec-2023, Manuscript No. AGBIR-23-123215; , Pre QC No. AGBIR-23-123215 (PQ); Editor assigned: 07-Dec-2023, Pre QC No. AGBIR-23-123215 (PQ); Reviewed: 25-Dec-2023, QC No. AGBIR-23-123215; Revised: 03-Jan-2024, Manuscript No. AGBIR-23-123215 (R); Published: 11-Jan-2024, DOI: 10.35248/0970-1907.24.40.801-806

Copyright: This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http:// creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.