Agricultural and Biological Research

RNI # 24/103/2012-R1

Research Article - (2021) Volume 37, Issue 6

Okra is a popular crop in Cameroon but average yields remain low due to its cultivation as a minor crop, limited availability of improved varieties, poor soil fertility and high cost of chemical fertilizers. The main aim of this work was to evaluate the potential of cheap and locally available cocoa pod husk and plantain peels to improve soil fertility and okra production in western Cameroon. The experimental design in the field was a Completely Randomized Block Design (CRBD) with six treatments and three repetitions, namely: control or natural soil (T0), plantain peels powder at 3 tons ha-1 (T1), cocoa pod husk powder at 8 tons ha-1 (T2), NPK 12-14-19 at 250 kg/ha (T3), plantain peels powder+NPK 12-14-19(T4) and cocoa pod husk powder+NPK 12-14-19 (T5). The soil was analysed before and after treatment using standard laboratory procedures. The data were then subjected to statistical analysis. The main results reaveled that the control soil was moderately acidic (pH 5.4) but treatments raised the pH to 6.3, 6.2, 6.1, and 5.8 for T2, T5, T4 and T1, respectively. The C/N ratio dropped from 15.23 (T0) to 8.4 (T4) and 10.8 (T5) probably portraying a higher microbial activity in those treatments. T4 plants showed the best growth performance meanwhile T0 plants showed the least performance. The highest fresh yield of Okra was recorded for T5 plants. Apart from T3, all treatments showed a high Benefit-to-cost ratio (BCR>2). However, T5 was the most economically profitable treatment, with a profit rate of 658% and a BCR of 7.58 standing out as the most recommended treatment to farmers for okra cultivation.

Abelmoschus esculentus; Cocoa pod husk powder; Plantain peels powder; Soil amendment; Yield; West Cameroon

World annual production of okra stands at 8.9 million metric tons with an average yield of 7.5 tons per ha [1,2]. Nigeria is the second largest producer of Okra in the world after India with an average production of 2.7 million tons from about 1.4 million hectares. In Cameroon, okra ranks third after tomatoes and pepper in terms of vegetable production [3]. Okra production in Cameroon is estimated to be 100,025 tons per year, with a yield of 2,719.8 tons per ha, which is below the average yield of Africa and the world. Although okra is very popular in Cameroon, yields remain low due to low soil fertility [4]. Chemical fertilizers have become expensive and almost beyond the reach of poor farmers [5]. Both organic and inorganic fertilizers have a potential role in agricultural development [6]. The benefits of chemical fertilizers have been extensively demonstrated since the ‘green revolution’, as they played an important role in boosting agriculture [7]. However, crop production with inorganic fertilizers has not been sustainable due to its high cost and scarcity as well as its negative effects on soils as soil acidification, leaching, nutrient imbalance and pollution. Hence, there is a new interest in the use of agricultural wastes by the dominant resource farmers. The recycling of nutrients as soil organic amendments can lead to the sustainable use of agricultural waste and may become a practice with economic and environmental benefits. Nowadays, a variety of wastes (straw, pulp, stover and husk) is generated from food and agricultural products processing industries such as olive oil mills, sugar industries, wineries, coffee and chocolate industries. World production of cocoa beans by the main producing countries (Brazil, Nigeria, Ecuador, Ghana, Côte d’Ivoire, Cameroon and Indonesia) during 2013-2014 harvest periods was estimated at 4.3 million tons and has increased over the last decade. Each ton of dry beans produced generates approximately 10 tons of cocoa pod husks and the global burden of pod husk waste continues to increase well over 40 million tons. With commercial interest centered on cocoa beans, the dry cocoa shells which are the main by-product from the chocolate industry are often burnt for fuel or used as mulch to increase soil fertility. Cocoa shells are rich in polysaccharides mainly cellulose and little lignin, as well as in phenolic compounds which exert antioxidant and antimicrobial effect. In addition, cocoa shells can remove several heavy metals from very acidic solutions as well as absorb and hold water that can be released gradually to the soil. Thus, cocoa shells can be used in combination with other organic materials to produce substrates for plant cultivation. Alternatively, cocoa shells can be used to produce material for soil amendment, since its addition to the soil as a biofertilizer increases soil fertility and crop production. Severe soil nutrient depletion and declining agricultural productivity due to a reduction of soil organic matter (SOM) and nutrient imbalances are major constraints in most tropical agricultural soils. Soil nutrient depletion is a major concern which is directly linked to food insecurity due to unsustainable intensified land use [8]. Nutrient losses are only partially compensated by natural and man-made inputs, hence maintaining an appropriate level of SOM and ensuring the efficient biological cycling of nutrients is crucial to the success of soil management and agricultural productivity strategies [9,10]. A variety wastes such as cocoa pod husk, plantain peels, rice husk, palm kernel cake wastes, potato peels, amongst others are abundantly generated in large quantities and often abandoned in field sites, littered in the surrounding, constituting foul odors, breeding grounds for pathogenic micro-organisms and environmental pollutants. These huge, cheap, unused organic wastes are an excellent source of humus and can be recycled for use as bio fertilizers considering the growing deficiency of plant nutrients in crop fields, high cost and low efficiency of synthetic fertilizers. Compost and biochar technologies are often expensive and involve a lot of technicalities for the local farmer to understand. Nevertheless, many findings [11,12] have shown success of simple techniques such as incorporation of organic wastes into the soil. Simeon and Ambah carried out amendments under controlled conditions like greenhouses, screen house, which do not reflect the farmers’ field conditions, hence, farmers’ adoptions of such research results are often limited [13]. Although several studies have been carried out on the use of cocoa pod husk, ash, biochar, compost as a fertilizer and or as soil amendment for the cultivation of some crops in Nigeria, Ghana and other parts of the world, there is little or no information on the use of cocoa husk and plantain peels powder in the cultivation of okra in Cameroon. Many questions still require answers, for example, can cocoa husk and plantain peels powders be used to improve soil quality? Can they replace commercial synthetic fertilizers? Can they improve crop growth and yield attributes? The main objective of this work is therefore to evaluate the potentials of cocoa pod husk powder and plantain peels powder as manures in the production of Okra. This study enables to provide information to farmers, agricultural students, industry, community and the research society on the recycling and reuse of organic wastes such as cocoa husk and plantain peels powders.

Study site

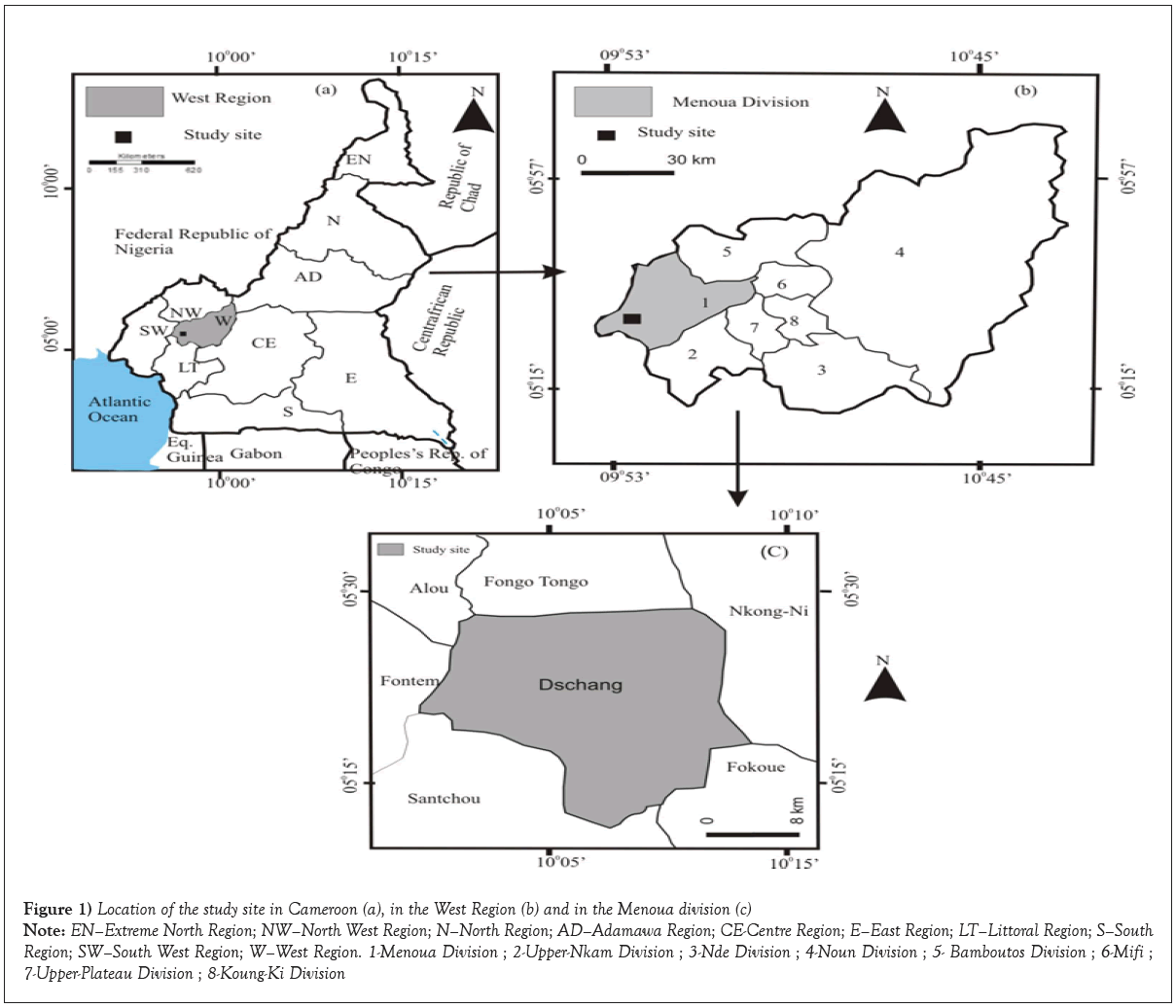

The field experiment was conducted at the teaching and research farm of the Faculty of Agronomy and agricultural Sciences (FASA) of the University of Dschang (Figure 1). Dschang is the headquarter of the Menoua Division and covers a surface area of 262 km2. Geographically, Dschang is located between latitudes 5°10' and 5°38'N and between longitudes 9°50' and 10°20'E. The climate of Dschang is the Cameroon altitude climatic type (Equatorial monsoon), characterized by one short dry season of five months (mid-November to mid-March) and one long rainy season of nine months (mid-March to mid-November). The average annual rainfall 1750 mm, a mean annual temperature of 22.5°C [14]. The vegetation is grassland, wooded savannah and mountain forests. The zone is drained by a fifth order stream (Menoua), through the contribution of many streams that take rise from the high elevation Santchou Cliff. The zone is located on the southern slopes of Mount Bambouto in the Cameroon Western highlands and forms the northern edge of the Mbo plain. The relief is mountainous with many plains and plateaus. The mean altitude is 1,500 m above sea level. It is characterized by various volcanic products covering the basement granitoids [15,16]. The basement rocks in Dschang consist of Neoproterozoic granitegneiss, Late Proterozoic granitoids intruded within the granite gneiss and basaltic dykes that out crop in the two previous units. The soils are ferrallitic at the midslopes, hydromorphic at the swampy valleys meanwhile the hill tops are occupied by lightly evolved erosional soils. The main activity of the inhabitants is agriculture as well as commercial activities. Arts and craft also play an essential role in the economy of the study area. This includes beautiful traditional regalia, jewelries, ceramics and textiles often featuring elaborate embroidery.

Figure 1: Location of the study site in Cameroon (a), in the West Region (b) and in the Menoua division (c) Note: EN–Extreme North Region; NW–North West Region; N–North Region; AD–Adamawa Region; CE-Centre Region; E–East Region; LT–Littoral Region; S–South Region; SW–South West Region; W–West Region. 1-Menoua Division ; 2-Upper-Nkam Division ; 3-Nde Division ; 4-Noun Division ; 5- Bamboutos Division ; 6-Mifi ; 7-Upper-Plateau Division ; 8-Koung-Ki Division

Experimental design and land preparation

Land preparation was done from the 10th to the 20th of January 2021. It involved clearing, tilling, pegging, separation of land into blocks and experimental units, leveling of beds, putting in place of placards per experimental unit and erecting a fence round the farm (to prevent stray animals from gaining access). The experimental layout was a CRBD with three blocks, six treatments, three replications and 18 Experimental Units (EU). Each block was comprised of 6 experimental units (4 m2 each) and 6 treatments namely: control (T0), plantain peels powder at 3 tons ha-1 (T1), cocoa pod husk powder at 8 tons ha-1 (T2), NPK 12-14-19 at 250 kg/ha (T3), plantain peels powder+NPK 12-14-19(T4), cocoa pod husk powder+NPK 12-14-19 (T5). The experimental units were separated by a 0.5 m distance within the same block, while the blocks were 1 m apart.The experimental plot occupied a total surface area of 333 m2.

Collection and preparation of plant materials

The plant materials used for this experiment are cocoa pod husk powder and plantain peels powder. Fresh CPH were obtained from a cocoa farm in Tiko while plantain peels were obtained from households in Bakoko in Limbe (South-west region of Cameroon). The fresh samples of cocoa pod husk and plantain peels were weighed on a balance. The mass obtained for the fresh samples were 68.3 kg (68300 g) and 71.93 kg (71930 g) for CPH and PPP, respectively. The fresh samples were washed with tap water and sun dried for one month. The dried CPH and plantain peels were crushed into smaller pieces before milling into powder using a milling machine. The mass of plant materials obtained after milling were 15 kg (15000 g) for cocoa pod husk and 8.6 kg (8600 g) for plantain peels.

Application of plantain peels and cocoa pod husk powder

The plantain peels and cocoa pod husk powder were applied two weeks prior to seeding. Cocoa pod husk was applied at the rate of 8 tons per ha, while plantain peels was applied at the rate of 3 tons per ha. Treatments where plant materials were in association with NPK 12-14-19 received half the dosage of plant materials and half the dosage of NPK 12-14-19. Plant materials were evenly spread and incorporated at a depth of 30 cm per experimental unit.

Planting and management

Seeds were sown on the 18th of February 2021. The variety sown was Kirikou which is an early maturing, vigorous variety with a good branching system. The seeds were bought in a farmer’s shop in marché A (Dschang, Cameroon). Prior to sowing, pegging and tracing of planting lines was done for each experimental unit. Each experimental unit was made up of four planting lines perpendicular to the length of the unit. Seeds were sown at a 5 cm depth into the soil to facilitate germination, with an inter row spacing of 50 cm and an intra-row spacing of 40 cm, with 3 seeds sown per hole. Seeds germinated 5 days after sowing and the %germination was calculated for each treatment in the 3 blocks. Two weeks after germination, thinning was carried out to two plants per stand leaving only one plant for follow-up.

Plant management involved watering, fertilizer application, weeding, and pest and disease control. Plant management started after germination with watering and was done daily with a watering can till the onset of rains. NPK 12-14-19 fertilizer was applied two weeks after germination at the rate of 250 kg/ha. 200 g of fertilizer was applied to experimental units needing combination of NPK and plant material, while 400 g of fertilizer was used for EU with NPK as sole treatment. Weeding was done manually once every week. Pest and disease management involved both natural controls but most especially chemical control. The main problem encountered in the field was insects which caused serious damages to plant leaves. The most prominent pest encountered on crops was Snails (Theba pisana) that caused damage to plant leaves. Thus, Limark, a mollusicide was applied at the rate of 5 g per plant affected. Whiteflies (Bemisia tabaci) caused direct damage (sucking of plant sap and removing plant nutrients thereby weakening the plant) and indirect damage (leaf curl disease of okra). Insect pest were manged by chemical control.The following insecticides were used for control; Debaras (imidacloprid WG), Optimal 20 SP (Acetamiprid 200 g/kg; SP) Parastar 40 WP (20 gr/L Imidachlopride+20 gr/L Lambdacyhalothrine), Paraforce 50 Ml (Chlorpyriphos-Ethyl 600 g/l;EC), Cicapsids 50 Sc (Fipronil 50 g/L). Fungicides were also applied as a prevention against fungi diseases namely; Agromil super 66 WP (6% Metalaxyl-M+60% Copper oxide), Monchamp, fungichamp (120 g/kg Cymoxanil+600 g/kg mancozebe), Flash one 36 WP (chlorothalonil 30%+Cymoxanil 6%). Application was done once a week following recommended doses as stipulated for the crop.

Plant data collection

The data collection on growth parameters started two weeks after planting. Five sampling plants were selected from the middle rows and data collected per experimental unit. Growth parameters measured include plant height (cm), stem diameter (cm), leaf length (cm) and leaf width (cm) and number of leaves. The leaf area index was calculated as the product of leaf length, leaf width and a constant (0.75) [17]. The yield data was collected from the 12th- 14th week on the same sampling plants used for growth parameters. Yield parameters collected were pod length (cm), pod diameter (cm), number of pods per plant and pod weight (tons per ha).

Soil sample collection and laboratory analysis

Soil samples were collected at the 0-30 cm depth (rooting zone) for each experimental unit immediately after experimental units were formed and at the end of the second harvest. A single composite sample was formed from the 3 blocks which was then placed in a clean plastic, labelled and taken to the laboratory for analysis. At the end of the experiment, a total of 5 soil samples were collected representing the five amendments applied to the soil. Samples were collected from EU with same treatments and a composite sample formed per treatment.

The soil physico-chemical properties were determined at the “Unite de Recherche d’Analyse des Sols et de Chimie d’Environnnement” (URASCE) of the Faculty of Agronomie and Agricultural Sciences of the University of Dschang (Cameroon), following standard procedures [18]. Thus, particle size distribution was measured by the Robison’s pipette method. The pHH2O was determined in a soil/water ratio of 1:2.5 and the pH-KCl was determined in a soil/KCl solution of 1:2.5. The Organic Carbon (OC) was measured by Walkley-Black method. Total Nitrogen (TN) was measured by the Kjeldahl method. Available phosphorus was determined by concentrated nitric acid reduction method. Exchangeable cations were analyzed by ammonium acetate extraction at pH7. The Cation Exchange Capacity (CEC) was measured by sodium saturation method.

Statistical analysis

The data collected were subjected to one-way Analysis of Variance (ANOVA) to test the effect of the different treatments on growth and yield parameters. When there was a significant difference, Duncan’s test was applied for mean separation. The Pearson’s correlation coefficient was used to establish a relation among the growth and yield parameters. For statistical analysis, SPSS software, version 20.0, was used.

Economic analysis

Calculations of the Net Profit (NP), Marginal Net Return (MNR), BCR, and the PR was done for the various soil treatments, where PR%=(BCR-1) × 100 [19]. Values of the average yield, average cost and average price were used for calculations in this economic analysis. The Gross Benefit (GB) of a fertilizer treatment is obtained by multiplying the yield per treatment by the unit price per kg of Okra. The Operation Cost (OC) is comprised of the Fertilizer Cost (FC), Transport Cost (TC), Fertilizer Spreading Cost (FSC), Marginal Net Return (MNR) and the investment interest (II). The MNR was obtained by multiplying the unit price of the okra and the difference between the yield with fertilizer use and the yield without fertilizer use. The MNR the difference between the Gross Revenue (GR) and the Revenue Cost of Fertilizers (RCF), Where GR is the Average yield multiplied by the unit price per kg of Okra. The RCF was calculated as interest rate (4.25% of operation per annum) plus operation cost. For BCR>1, profit is expected, but if BCR<1, no profit is expected. However, under the humid tropics, a BCR≥2 implies that a 100% of the total investment is expected and that the application method or fertilizer type can be popularized or recommended.

Soil properties and composition of plantain peels and cocoa pod husk

The soil characteristics before and after treatment are compiled in table 1. The soils were clayey in nature. The pH-H2O ranged from 5.4 in T1 to 6.3 in T2. The following trend was noted: T2 >T5>T4>T3>T1 >T0. The pH-KCl was less than the pH-H2O for both control and treated soils. The organic carbon varied from 2.16% to 5.94%. T0 recorded the highest percentage for nitrogen while T5 showed the least. The total nitrogen varied between 0.39% in T0 and 0.20% in T5. The total available phosphorus ranges from 24.12 mg/kg in T4 to 21.82 mg/kg in T3. The exchangeable Ca ranges from 2.6 cmol/kg in T0 to 1.256 cmol/kg in T3. The exchangeable Mg varied from 1.32 cmol/kg in T5 to 0.98 cmol/kg in T2. The exchangeable K followed the trend T4>T5>T3>T2 >T1 >T0. The exchangeable Na varies between 0.08 cmol/ kg in T0 and 0.01 cmol/kg in T5 and T1. The Sum of Exchangeable Bases (SEB) ranges from 5.38 cmol/kg in T4 to 4.05 cmol/kg in T3. The CEC varied from 18.72 cmol/kg in T0 to 14.78 cmol/kg in T1. The C/N ratio fluctuated between 17.73 in T3 to 8.35 in T4.

The calculation of some nutrient ratios revealed that Ca/Mg ratio varied from 2.41 in T0 to 1.09 in T4. The base saturation varied from 32.12 in T4 to 23.5 in T0. The Mg/K ratio ranged from 1.69 (T0) to 0.62 (T4). The (Ca+/Mg/K) ratio varied from 5.75 (T0) to 1.48 (T3). The (Ca/Mg/K) ratios indicated a cationic imbalance. Amongst all treatments, only T0 showed a (Ca/Mg/K) ratio close to the ideal situation (76% Ca, 18% Mg and 6% K) required for best plant absorption. The Coefficient of Relative Concentration (CRC) indicated that for both control and treated soils, K was the most concentrated cation determining the direction of cationic equilibrium (Table 1).

| Parameter | T0 | T1 | T2 | T3 | T4 | T5 | ||

|---|---|---|---|---|---|---|---|---|

| Particle size distribution (%) | fine sand | 9 | / | / | / | / | / | |

| Coarse sand | 16 | / | / | / | / | / | ||

| Fine silt | 18 | / | / | / | / | / | ||

| Coarse silt | 15 | / | / | / | / | / | ||

| Clay | 42 | / | / | / | / | / | ||

| Textural class | Clay | / | / | / | / | / | ||

| pH-H2O | 5.4 | 5.8 | 6.3 | 5.6 | 6.1 | 6.2 | ||

| pH-KCl | 4.9 | 5.1 | 5.2 | 5.1 | 5.3 | 5.1 | ||

| DPH | 0.5 | 0.7 | 1.1 | 0.5 | 0.8 | 1.1 | ||

| Organic carbon (%) | 5.94 | 2.88 | 3.89 | 4.61 | 2.59 | 2.16 | ||

| Total nitrogen (%) | 0.39 | 0.22 | 0.29 | 0.26 | 0.31 | 0.2 | ||

| Exchangeable bases (cmol/kg of soil) | Ca | 2.6 | 2.45 | 2.15 | 1.25 | 2.15 | 1.45 | |

| Mg | 1.08 | 1.05 | 0.98 | 1.15 | 1.23 | 1.32 | ||

| K | 0.64 | 1.11 | 1.52 | 1.62 | 1.98 | 1.75 | ||

| Na | 0.08 | 0.01 | 0.02 | 0.03 | 0.02 | 0.01 | ||

| SEB (cmol/kg of soil) | 4.4 | 4.46 | 4.67 | 4.05 | 5.38 | 4.53 | ||

| CEC (cmol/kg of soil) | 18.72 | 14.78 | 15.25 | 16.75 | 16.75 | 16.45 | ||

| CECclay (cmol/kg of clay) | 6.84 | 9.02 | 7.47 | 7.53 | 11.57 | 12.13 | ||

| CEC OC (cmol/kg of Carbon) | 11.88 | 5.76 | 7.78 | 9.22 | 5.18 | 4.32 | ||

| P (mg/kg) | 22.58 | 22.97 | 22.28 | 21.82 | 24.12 | 23.08 | ||

| EC (mS/cm) | 0.03 | 0.02 | 0.02 | 0.02 | 0.02 | 2 | ||

| C/N ratio | 15.23 | 13.09 | 13.41 | 17.73 | 8.35 | 10.8 | ||

| Ca/Mg ratio | 2.41 | 2.33 | 2.19 | 1.09 | 1.75 | 1.1 | ||

| S/T (%) | 23.5 | 30.18 | 30.62 | 24.18 | 32.12 | 27.54 | ||

| Mg/K | 1.69 | 0.95 | 0.64 | 0.71 | 0.62 | 0.75 | ||

| (Ca+Mg)/K | 5.75 | 3.15 | 2.06 | 1.48 | 1.71 | 1.58 | ||

| Ca/Mg/K | 60/25/15 | 53/23/24 | 46/21/33 | 31/29/40 | 40/23/37 | 32/29/39 | ||

| CRC | 0.8/1.4/2.5 | 0.7/1.3/4 | 0.6/1.2/5.5 | 0.4/1.6/6.7 | 0.5/1.3/6.2 | 0.4/1.6/6.5 | ||

| ESP | 0.43 | 0.07 | 0.13 | 0.18 | 0.12 | 0.06 | ||

Note: T0: Control, T1: Plantain peels powder, T2: Cocoa pod husk powder, T3: NPK 12:14:19, T4: Plantain peels powder+NPK, T5: Cocoa pod husk powder+NPK 12- 14-19; SEB: sum of exchangeable bases; CEC Clay: Cation exchange capacity of clayey fraction; CEC OC: Cation exchange capacity of organic carbon fraction; P: available Phosphorus, EC: Electrical Conductivity

Table 1: Soil properties before and after treatment

Plantain peels powder (unripe), recorded the highest levels of organic carbon (6.14%), organic matter (10.59%), total nitrogen (0.994%), Mg (1846.80 mg/ kg), K (45375.87) mg/kg, Na (1213.42 mg/kg), P (1942.70 mg/kg). Cocoa pod husk powder, on the other hand had a lower concentration of all the other elements analysed except Ca (3840.00 mg/kg). However, plantain peels powder has a lower C/N ratio (6) compared to cocoa pod husk powder (16) and this is very crucial for microbial decomposition (Table 2).

| Organic powder | pH-H2O | OC | Total N | C/N | Ca | Mg | K | Na | P |

|---|---|---|---|---|---|---|---|---|---|

| (%) | (%) | (mg/kg) | |||||||

| Plantain peels | 6.5 | 6.14 | 0.99 | 6 | 1040 | 1846.8 | 45375.87 | 1213.42 | 1942.7 |

| Cocoa pod husk | 5.9 | 5.18 | 0.32 | 16 | 3840 | 1652.4 | 27099.06 | 939.03 | 862.85 |

Table 2: Nutrient composition of organic wastes powder used for soil treatment

Growth parameters

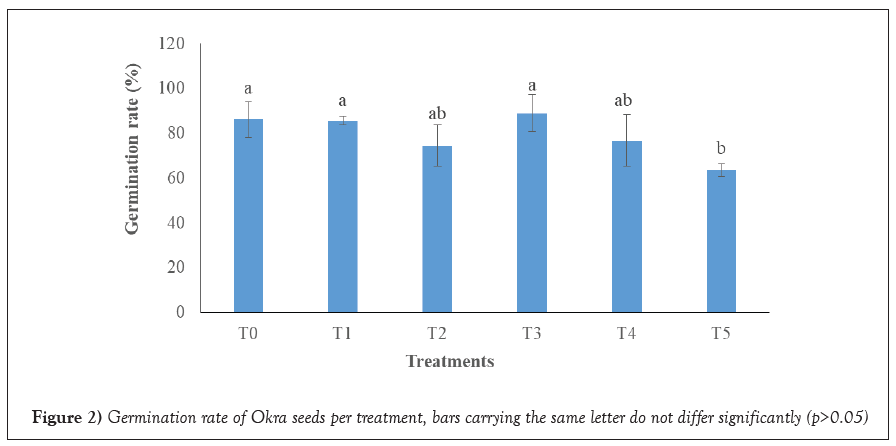

The germination rate ranged from 61.67 to 98.33%. The germination rate was significantly (p˂.05) lower in T5 (cocoa pod husk+NPK 12-14-19) compared to T0 (Control), T1 (plantain peels powder) and NPK 12-14-19 (Figure 2).

Figure 2: Germination rate of Okra seeds per treatment, bars carrying the same letter do not differ significantly (p>0.05)

The number of leaves of okra plants was significantly influenced by the applied fertilizers. All treatments experienced an evolution in the number of leaves from the first week of data collection to the seventh week as shown in Figure 3a. The T5 plants showed number of leaves which outclassed that of control, NPK, PPP, CPHP, PPP+NPK12-14-19. However, control showed the lowest performance in terms of number of leaves.

Figure 3: (a-e) Variation of leaf number of, plant height, stem diameter, leaf length and leaf width per treatment.

Note: T0( ), T1(

), T1( ), T2(

), T2( ), T3(

), T3( ), T4(

), T4(  ), T5(

), T5( )

)

The plant height increased from the first to the seventh week of data collection regardless of the treatment (Figure 3b). T5 treatments had the tallest plants while unfertilized plants (control) produced the shortest plants compared to the other treatments.

The stem diameter of okra plants was influenced by applied fertilizers as in Figure 3c. T5 produced plants with the largest stem girth as compared to other treatments. The control however recorded plants with the least stem diameter.

Leaf length increased for all treatments from week 1 to 7 of data collection (Figure 3d). In addition, T5 fertilized plants gave rise to the longest leaves, while the control had plants which were shortest in length.

Leaf width was enhanced by all the fertilizer treatments (Figure 3e). T5 had the widest leaves while the control had leaves with the smallest width.

Leaf area index increased for all treatments from the first week to the seventh week of data collection (Figure 4). T5 produced plants with the largest leaf area index while the control plants had the least leaf area index.

Figure 4: Variation of the leaf area index per treatment

Note: T0(  ), T1(

), T1( ), T2(

), T2( ), T3(

), T3( ), T4(

), T4( ), T5(

), T5(  )

)

Final growth parameters: 7th week of data collection

The growth parameters at the 7th week are compiled. Generally, for most of the growth parameters, T5 was significantly different from all other treatments giving rise to plants that performed best. Mean values for number of leaves followed the trend T5>T2 >T3>T1>T4>T0. Cocoa pod husk powder+NPK 12- 14-19 showed a highly significant difference in the number of leaves (p˂0.05) compared to the other treatments. T5 had the highest number of leaves (37.20 ± 10.56). However, the control had the least number of leaves amongst all the other treatments (26.40). The Plant height was significantly increased (p˂0.05) by the applied treatments in the order T5>T1>T2>T4>T3>T0. The tallest plants (91.47 ± 7.73) were recorded from the combined application of cocoa pod husk powder+NPK 12-14-19 (p˂0.05) which was significantly taller than of plantain peels powder+NPK (84.67 ± 8.12), NPK 12-14-19 (81.67 ± 4.81), and control (81.53 ± 6.19). The tallest plants were significantly not taller than those of plantain peels powder (90.60 ± 8.12) and cocoa pod husk powder (89.12 ± 6.47). The shortest plants were observed in the control (81.53 ± 6.19).The stem diameter equally showed a significant increase (p˂0.05) with treatments, with T5 as the most significant of all treatments. The largest stem diameter (1.91 ± 0.33) was recorded by T5 and the smallest (1.21 ± 0.19) on the control. The stem diameter of plantain peels powder, cocoa pod husk powder, NPK, plantain peels powder plus NPK treated plants did not differ significantly. The leaf length was significantly influenced by the applied fertilizers (p˂0.05). T5 showed no significant difference statistically from the other treatments except the control. T5 recorded the longest leaves (18.17 ± 1.88) while control plants had the shortest leaves (15.20 ± 2.86). However, T0 plants did not show any significant difference from plantain peels powder and cocoa pod husk powder treated plants with respect to leaf lengths. Over all, on the 7 th week, the leaf width from the control, plantain peels powder, cocoa pod husk powder, NPK, plantain peels powder mixed with NPK, cocoa pod husk powder mixed with NPK treatments were not significantly different (p>0.05) (Table 3).

| Growth paramètres | Treatments | p-value | |||||

|---|---|---|---|---|---|---|---|

| T0 | T1 | T2 | T3 | T4 | T5 | ||

| NL | 26.40 ± 7.11b | 27.40 ± 6.15b | 30.33 ± 6.81b | 29.13 ± 5.51b | 26.80 ± 5.94b | 37.20 ± 10.56a | 0.001 |

| PH (cm) | 81.53 ± 6.19c | 90.60 ± 8.12a | 89.12 ± 6.47ab | 81.67 ± 4.81c | 84.67 ± 5.16bc | 91.47 ± 7.73a | 0 |

| SD (cm) | 1.21 ± 0.19c | 1.44 ± 0.21b | 1.59 ± 0.28b | 1.54 ± 0.26b | 1.53 ± 0.28b | 1.91 ± 0.33a | 0 |

| LL (cm) | 15.20 ± 2.86b | 16.81 ± 3.03ab | 17.16±2.49ab | 17.93 ± 2.57a | 17.97 ± 2.67a | 18.17 ± 1.88a | 0.024 |

| LW (cm) | 16.50 ± 3.13a | 19.22 ± 4.52a | 17.65 ± 3.03a | 18.73 ± 2.79a | 19.17 ± 2.89a | 19.23 ± 3.55a | 0.157 |

| LAI (cm2) | 193.15 ± 65.47b | 250.53 ± 94.62a | 230.60 ± 67.58a | 256.00 ± 67.47a | 262.26 ± 71.50a | 264.35 ± 67.79a | 0.057 |

Note: a, b, c, ab, bc Means on the same line with different letters differ significantly (p<0.05); The values are the statistical means and the letters represent the significance level. NL: Number of Leaves, PH: Plant Height, SD: Stem Diameter; LL: Leaf Length; LW: Leaf Width, LAI: Leaf Area Index

Table 3: Plant growth parameters at the 7th week of data collection

Lastly, the leaf area index significantly increased (P˂0.05) by the combined application of cocoa pod husk powder+NPK 12-14-19 (T4) compared to the other treatments. T5 plants recorded the largest leaf area index (264.35 ± 67.79) while control recorded the least (193.15 ± 65.47), even though there was no significant (P>0.05) difference amongst the treatments.

Crop yield parameters at 1st and 2nd harvests

There is a significant difference (p˂0.05) in the number of pods during the first and second harvest. Also it can be deduced that the number of pods for various treatments was more significantly different during the second harvest than the first harvest (p=0.010). T1 (3.47 ± 0.90) and T5 (6.07 ± 3.08) had the highest number of pods at first and second harvest respectively compared to other treatments while NPK fertilized plants demonstrated the least number of pods (2.55 ± 0.82) in the first harvest and the control (3.27 ± 0.70) for the second harvest. At both harvest, the number of pods per treatment were not statistically different from each other. Regarding the pod weight, there was a significant (p˂0.05) difference during the first harvest with T2 recording a highly significant difference compared to other treatments as well as producing the heaviest pods (17.23 ± 4.02). Also, there was no significant difference between treatments (p>0.05) in the second harvest. The pod diameter was statistically similar (p˂0.05) in the first harvest for all the treatments except for T3 and T4 which were significantly different from the other treatments. T3 recorded pods with the smallest diameter (2.05 ± 0.33). All treatments showed no significant difference during the second harvest (p>0.05). Cocoa pod husk powder was significantly different in terms of pod length compared to other treatments (p˂0.05) in the first harvest. Although NPK fertilized plants had the shortest pods. No significant difference was recorded for all treatments during the second harvest (p>0.05).

The mean fresh yield of okra ranged from 6951.07 ± 2652.26 to 3760.00 ± 934.50. The yield increased as follows: T5>T2>T1>T4>T0>T3. A significant difference (p˂0.05) existed between T5, T1, T4, and T0. The yields of (T5 and T3), (T1, T4, T0, T3), (T1, T2) were comparable (statistically similar). T3 showed the lowest values for yields (Table 4).

| Yield parameters | Harvest number | Treatments | p-value | |||||

|---|---|---|---|---|---|---|---|---|

| T0 | T1 | T2 | T3 | T4 | T5 | |||

| Number of pods | 1 | 2.75 ± 1.02ab | 3.47 ± 0.90a | 3.40 ± 1.12a | 2.55 ± 0.82b | 3.04 ± 1.33ab | 3.20 ± 1.01ab | 0.049 |

| 2 | 3.27 ± 0.70b | 4.85 ± 2.42ab | 4.80 ±1.57ab | 4.07±1.33b | 4.87 ± 2.03ab | 6.07 ± 3.08a | 0.01 | |

| Pod weight (g) | 1 | 15.57 ± 3.63ab | 14.43 ± 5.15ab | 17.23 ± 4.02a | 9.58 ± 3.24c | 11.82 ± 4.05bc | 15.29 ± 6.31ab | 0.001 |

| 2 | 14.00 ± 4.15a | 15.38 ± 4.52a | 14.79 ± 2.01a | 13.10 ± 3.99a | 13.54 ± 3.97a | 13.33 ± 2.36a | 0.678 | |

| Pod diameter (cm) | 1 | 2.55 ± 0.31a | 2.60 ± 0.58a | 2.84 ± 0.31a | 2.05 ± 0.33b | 2.22 ± 0.69b | 2.58 ± 0.39a | 0 |

| 2 | 2.55 ± 0.29a | 2.52 ± 0.20a | 2.54 ± 0.11a | 2.37 ± 0.39a | 2.47 ± 0.30a | 2.47 ± 0.20a | 0.414 | |

| Pod length (cm) | 1 | 6.30 ± 0.71ab | 5.65 ± 1.05bc | 6.75 ± 1.03a | 5.17 ± 0.90d | 5.45 ± 1.21cd | 6.09 ± 0.09ab | 0 |

| 2 | 5.83 ± 0.80a | 6.40 ± 1.18a | 6.27 ± 0.64a | 5.67 ± 1.07a | 5.95 ± 0.96a | 6.23 ± 0.57a | 0.201 | |

| Yield (kg/ha) | / | 4465.00 ± | 5670.83 ± | 6433.33 ± | 3760.00 ± | 5110.07 ± | 6951.07 ± | 0 |

| 939.49cd | 1745.97bc | 1282.25ab | 934.50d | 1664.72c | 2652.26a |

Note: a, b, c, ab, bc, cd Means on the same line with similar letters do not differ significantly (p>0.05); Means on the same line with different letters differ significantly (p<0.05)

Table 4: Okra yield at 1st and 2nd harvests

Correlations among yield and growth parameters

The Pearson’s product moment correlation between the growth and yield parameters at the 7th week of data collection is presented. The number of pods at second harvest showed moderate positive correlation with the number of leaves and stem diameter at week seven of data collection. The weight of pods during the first and second harvest showed an averagely positive correlation with the plant height at week seven of data collection. The average pod length during the first and second harvest showed an average positive correlation with the plant height at week seven after germination. The number of pods during the first harvest showed a low positive correlation with the plant height and stem diameter at the seventh week after germination. The average number of pods for the first harvest was averagely positively correlated to the number of leaves and plant height at week seven (Table 5).

| Parameters | NL | PH | SD | LL | LW | LAI |

|---|---|---|---|---|---|---|

| NP1 | 0.04 | 0.21* | 0.24* | 0.06 | 0.16 | 0.12 |

| NP2 | 0.35** | 0.15 | 0.43** | 0.11 | 0.13 | 0.12 |

| WP1 | 0.2 | 0.35** | 0.17 | -0.08 | 0.01 | -0.04 |

| WP2 | -0.01 | 0.30** | -0.08 | 0.01 | 0.1 | 0.08 |

| AvPD1 | 0.25* | 0.25* | 0.16 | -0.06 | -0.01 | -0.04 |

| AvPD2 | 0.12 | 0.11 | -0.06 | -0.17 | -0.078 | -0.13 |

| AvPL1 | 0.18 | 0.27** | 0.15 | 0.01 | 0.02 | 0.01 |

| AvPL2 | 0.07 | 0.36** | 0.06 | 0.04 | 0.14 | 0.11 |

Note: **. Correlation is significant at the 0.01. *. Correlation is significant at the 0.05. NP1: Number of Pods from first harvest; NP2: Number of Pods for first harvest; AvPD1: Average Pod Diameter for first harvest; AvPD2: Average Pod Diameter for second harvest; AvPL1: Average Pod Length for first harvest; AvPL2: Average Pod Length for second harvest; NL: Number of Leaves, PH: Plant Height, SD: Stem Diameter; LL: Leaf Length; LW: Leaf Width, LAI: Leaf Area Index

Table 5: Correlation between growth and yield parameters at the 7th week of data collection

Economic analysis of the treatments

T5 was the most economically profitable treatment while T3 was expensive compared to the other treatments. The BCR trends as follows: T5>T2>T1>T4>T0 >T3. In addition, the total expenditure was far below the total gross revenue implying a positive balance sheet for all the soil treatments. Compared to T0, T3 recorded the lowest gross revenue as well as the lowest marginal net returns and profit rate (-290%). Thus apart from T0, all the other treatments are profitable with T3 as the least and T5 the most profitable (Table 6).

| T | Y (Kg/ha) |

EY (kg/ha) |

GR (FCFA) |

FC (FCFA) |

FSC (FCFA) |

FTC (FCFA) |

TEEY (FCFA) |

II | RCF (FCFA) |

MNR (FCFA) |

BCR | PR (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T0 | 4465.00 | 0 | 2232500 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| T1 | 5670.83 | 1205.83 | 2835415 | 90000 | 25000 | 18000 | 133000 | 5652.5 | 138652.5 | 602915 | 4.35 | 335 |

| T2 | 6433.33 | 1968.33 | 3216665 | 80000 | 25000 | 32000 | 137000 | 5822.5 | 142822.5 | 993165 | 6.95 | 595 |

| T3 | 3760 | -705 | 1880000 | 150000 | 25000 | 2500 | 177500 | 7543.7 | 185043.8 | -352500 | -1.9 | -290 |

| T4 | 5110.07 | 645.07 | 2555035 | 120000 | 25000 | 10250 | 155250 | 6598.1 | 161848.2 | 322535 | 1.99 | 99 |

| T5 | 6951.07 | 2486.07 | 3475535 | 115000 | 25000 | 17250 | 157250 | 6683.1 | 163933.2 | 1243035 | 7.58 | 658 |

Note: T: Treatment; Y: Mean Yield; EY: Extra Yield (due to fertilizer use);FC: Fertilizer Cost; TEEY: Total Expenditure on Extra Yield; FSC: Fertilizer spreading cost; FTC: Fertilizer transport cost; OC: Total cost; II: Interest on investment (4.25% per annum in Cameroon); RCF: Revenue Cost of Fertilizer; MNR: Marginal Net Return; BCR: Benefit-to-Cost Ratio; PR (%): Profit Rate (due to soil treatment); FCFA: Francs French Currency in Africa; 1US $ 1≈600 FCFA (May 2016).Cost of (500frs). Each value is a mean of 3 replicates

Table 6: Economic significance of the different soil treatments on okra production

Influence of different treatments on soil properties

In all treatments, a slight rise in soil pH from moderately to slightly acidic was observed. This pH interval is best for the cultivation of Okra and indicates that the different treatments improved the soil fertility. T2 soils recorded the highest pH which correlates with the trend observed [20,21]. Apart from exchangeable K, all exchangeable bases decreased in the treated soils compared to the control. The exchangeable Ca was low to very low, the Mg and Na content were low. These findings are contrary to those observed by [22-23] who reported an increase in exchangeable bases upon cocoa pod ash and husk application. This decrease could imply high uptake of basic cations by the plants. Previous studies on Okra and Arabica coffee seedlings revealed that cocoa husk increased uptake of N, P, K, Ca and Mg [22-26]. The control and treated soils showed a moderate CEC implying that nutrients were less susceptible to leaching hence cations were supplied to the soil for uptake by plants. This is contrary to the findings of reporting a significant variation in the concentration of exchangeable cations of ammended soils, with ground plantain peels recording the highest Na and Ca concentration. The phosphorus content of the soils was adequate for crop production. Apart from T3 and T0, all other treatments indicated an OM of good to very good quality in T4, which implies that microbial activities greatly improved and might have enhanced early mineralization of the nutrients present in these treatments. This is consistent with the findings [27]. The soils had a low base saturation which could indicate the presence of acid cations (Al3+) that are toxic to plants. The soils had a very low Ca/Mg ratio, while the Mg/K ratio indicated an Mg deficiency and the Ca/Mg/K ratio indicated a cationic imbalance for all other treatments except T0 which was closest to the ideal situation (76% Ca, 18% Mg, and 6% K) for the optimum availability for plant absorption. The CRC indicated that K was the most concentrated cation determining the direction of cationic equilibrium. The exchangeable sodium percentage was low implying there are no Na problems susceptible of negatively affecting crop performance following different treatments. Furthermore, the CEC clay indicated that the main clay mineral present in the soils is kaolinite. The high exchangeable K of the soils could be attributed to previous land use involving the addition of potash fertilizers. The contribution of OM was as follows: T0 >T3 >T2 >T1>T4>T5.

Implication of the different treatments on Okra performance

The cocoa pod husk powder and plantain peels powder showed varying amounts of N, P, K, Ca, Mg and some other micronutrients. This corroborates with the works [28-32]. The T5 plants showed the best performance for all growth parameters, compared to the other treatments. Treatment T5 resulted in a significant increase in plant height, number of leaves, stem diameter and the leaf area index. This can be explained by the poor germination rate resulting in a low plant density compared to the other treatments. Hence, there was little or no competition between plants and each plant had adequate nutrients essential for its growth. Also, better performance by this treatment can be explained by the fact that the combination of the two materials ensured a more balanced nutrition. While the powder husk was effective in increasing K and Ca, NPK fertilizer was particularly effective in increasing N and P and the micronutrients. The high nitrogen and phosphorus supplied by both amendments in addition to those in the soil facilitated increased tissue differentiation, stimulated root development, increased stalk and stem strength, increased resistance to plant diseases. This trend is in line with that of Ayeni revealing a high cummulative yield on immediate and residual basis with the addition of NPK fertilizer to cocoa pod ash. Omogoye confirmed that NPK and it combinations with cocoa pod husk powder produced sorghum plants whose stem girth and seed yield outclassed those of cocoa pod ash, cocoa pod powder, NPK plus cocoa pod ash [33]. Other work revealed that varying levels of cocoa pod husk ash and cocoa pod husk powder increased vegetative parameters of radish. Generally T0 gave the lowest performamce for all growth parameters. This could mean that the nutrients in the soil were low, and with no amendment added, were insufficient to support the optimum plant growth. This could also be explained by the low base saturation which may have indicated the presence of acid cations (Al3+) that is toxic to plant growth. The T2 plants recorded the highest pod weight, pod diameter and pod length probably attributed to a number of factors: cocoa pod husk powder probably released macroand micronutrients into the soil which were obsorbed by the plants. The cocoa pod husk powder has been reported to increase soil macronutrients. Okenyi et al. observed that the application of organic amendments increased the population of soil microbes thereby significantly increasing the mineralization rate of N, P and K for plant uptake. Mg is known to be part of the chlorophyll molecule which is essential for photosynthesis. High values for all the parameters measured as a result of cocoa pod husk powder application could be due to the presence of Mg in the amendment which assisted in the process of photosynthesis hence taller plants, higher number of leaves, and increased fresh pod weight as documented by upon application of cocoa pod powder for black banished and radish production.

The NPK 12-14-19 (T3) recorded the least performance for all but one of the yield parameters. This could be due to its low nitrogen content which is a major nutritional element required for tissue differentiation and its role in increasing plant growth and development. This finding contradicts with whereby NPK treatments produced the highest number of fruits and the heaviest fruits as compared to the foliar and control treatments. Nevertheless, this fertilizer does not have the ability to raise soil pH on its own, so the low pH of the soils might have hindered the uptake of soil nutrients. The reduction in almost all yield parameters can also be attributed to the fact that all nutrients required for the plant were not present in the fertilizer and those in the soil could not supplement the nutrients that were deficient or inadequate in agreement.

The fresh yields of Okra are as follows: T5>T2>T1>T4>T0>T3. The highest yields obtained by T5 could be attributed to increased availability of macroand micronutrients from both amendments, stimulation of microbial activities which mineralized nutrients and made them available for uptake by the plant as reported by van Reeuwijk similar observations have been documented by Ojeniyi revealing that the addition of NPKF to cocoa pod ash increased plant P, K, Zn, Fe and Mn. This affirms the observation that NPK fertilizer in addition to Cphp increased the supply of N, P and K enhancing the availability of micronutrients in the soil. Omogoye also noted an improvement in fruit yields of chilies due to the combined application of cow-dung and NPK 20-10-10 at 1 t/ha on 1:6 weight combination.

Economic outcomes of the different treatments

The most economically viable soil treatment in terms of yield was achieved by T5 with a Profit Rate (PR) of 658% and a BCR of 7.58. According to Omogoye, a BCR value greater than 2 implies that at least 100% of the investment will be recovered from the yields. The combined application of cocoa pod husk powder and NPK (T5) can be popularized for the cultivation of okra. Compared to T0, there is a sharp drop of PR in T3 (-290%) compared to the other treatments indicated by its negative extra yield obtained from fertilizer application. Similarly, Hush Ash revealed that CPH is a source of K-fertilizer and has been used successfully as a source of K for maize; thus, cocoa production could yield a total amount of 7000 metric tons of potash annually, which amounts to about a total annual consumption of potash fertilizer in Nigeria.

In this study, the potential of cocoa pod husk and plantain peel powders were used to improve soil fertility and Okra (Abelmoschus esculentus) production in the Cameroon Western highlands. The main results revealed that although most of the soil characteristics didn’t improve much after treatment, the soil pH increased for all treatments with T2 showing the best efficiency in improving soil acidity and T4 was efficient in reducing the C/N ratio probably due to a higher microbial activity. The highest fresh yield of Okra was recorded by T5 (cocoa pod husk powder+NPK 12-14-19), followed by T2 (cocoa pod husk powder), next by T1 (plantain peels powder), then T4 (plantain peels powder plus NPK), T0 (control) and the lowest yield was shown by T3 (NPK 12-14-19). In addition, T5 produced the tallest plants, the highest number of leaves, the largest stem diameter, the largest leaf area index, meanwhile T0 recorded the lowest values for the afore mentioned parameters. The most economically viable treatment was T5 with a profit rate of 658% and a benefit-to-cost ratio of 7.58. Thus, T5 was the most recommended treatment as an alternative to chemical fertilizers, meanwhile NPK 12-14-19 is not recommended for the cultivation of okra in this locality. Secondly, okra in Dschang should be cultivated with the use of cocoa pod husk powder solely or cocoa pod husk powder combined with NPK 12-14- 19. Furthermore, more farmers should go into the cultivation of okra as an economic crop high yields and profit are obtained without soil amendment.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper

Citation: Azinwi Tamfuh P, Agbor-Ambang TS, Bitondo D, et al. Soil fertility Amendment using cocoa pod huskand plantain peels powders for Okra (Abelmoschus esculentus, kirikou variety) production in Dschang (Cameroon Western Highlands). AGBIR. 2021;37(6):204-212

Received: 02-Nov-2021 Accepted: 16-Nov-2021 Published: 26-Nov-2021

Copyright: This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http:// creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.