Agricultural and Biological Research

RNI # 24/103/2012-R1

Research Article - (2024) Volume 40, Issue 3

The objective of this study was to investigate the fiber properties of Acacia deccurens as an alternative raw material quality evaluation for pulp and paper production. Trees from an even aged stand with a similar stem diameter class were selected randomly. Wood discs were cross cut systematically from a log at the bottom (10%), middle (50%), and top (90%) position along the merchantable height, as well as a block of wood (2 cm × 2 cm × 2 cm), was taken from pith to periphery: at near pith (10%), middle (50%), and near bark (90%) of disk radius. Fiber properties were determined, and their change with tree height and distance from the pith to the bark were evaluated. The fiber length, fiber width, lumen diameter, and cell wall thickness were measured while the derived fiber values were computed from the measured fiber dimensions. All the data were analyzed using a two way analysis of variance. The results showed that the overall means were 1.37 mm, 39.60 μm, 9.68 μm, 1.93 μm, 0.39, 35.38, 24.82, and 0.09 for fiber length, fiber width, lumen diameter, cell wall thickness, runkle ratio, slenderness ratio, flexibility coefficient, and wall coverage ratio, respectively. A. deccurens was found to fulfill most of the derived fiber values for pulp and paper production, as any part of the tree portion along tree heights and from the pith to the periphery can be utilized for pulp and paper production.

Derived fiber values; Fiber dimension; Tree portion; Pith to periphery; Pulp and paper

The pulp is made of hardwood, softwood, agricultural residues, and other similar lignocellulosic materials. Hard wood and softwood pulp represent 95% of total global pulp production, with the remaining 5% coming from lignocellulosic materials, mainly agricultural residues and grasses [1]. World paper consumption in 2025 will be 500 million tonnes, an increase of around 1.6% per year. Pulp and paper consumption has increased globally and will continue to increase in the near future due to many reasons, which include population growth and industrialization in developing countries.

Ethiopia has a paper and paperboard per capita consumption of 1 kg per person per year, which has been growing by 10% every year. The consumption of paper and paper products is growing faster in Ethiopia due to the expansion of education and the rapid increase in disposable income. Perpetuated by these factors, the craving for paper has grown in Ethiopia. However, the country has not matched that appetite with sufficient local production to meet the mounting demand. There is a large outflow of funds for the purchase of pulp, paper and paper based articles. Ethiopia, on average, imported about USD 17 million worth of pulp from wood or other fibrous cellulosic material and USD 349 million worth of paper and paperboards. A continued supply of paper to meet these growing demands would require additional suitable raw materials to complement traditional sources of diminishing raw materials [2].

Despite the presence of many fast growing, widely agro ecologically adaptable indigenous and exotic woody species, imports of forest products, including pulp and paper, from other countries are increasing at an alarming rate in Ethiopia. The Acacia decurrens tree belongs to the species of Acacia section Botrycephalae, which is characterized by bi-pinnate adult foliage and flower heads, which are normally arranged in elongated racemes and are found in temperate areas of eastern and southeastern Australia. It is endemic in New South Wales, where it occurs chiefly on the coast and tablelands from the Hunter Valley south to the Australian Capital Territory. A. decurrens are shapely erect trees that grow to be 5-10 meters tall but sometimes attain 20–22 meter under favourable conditions, commonly with single, straight main stems, strong, shallow lateral roots [3].

A. decurrens was introduced into the central highlands of Ethiopia in the early 1990’s as short rotation forestry to counter urban firewood shortages arising from deforestation. It was introduced into state owned plantations in the north western Highlands around the same year. A. decurrens is an excellent source of fuel wood, pulpwood, hardboard production, building poles, tanning of hides, mine props, fence posts, valuable timber species, etc.

Fiber properties and derived fiber indices that determine the pulp yield, pulp and paper quality of the wood of A. decurence are not well documented, even though it is an abundant species. Therefore, the aim of this study was to evaluate the fiber properties of A. deccurens, in the context of potential raw material quality evaluation for pulp and paper production [4].

Site description

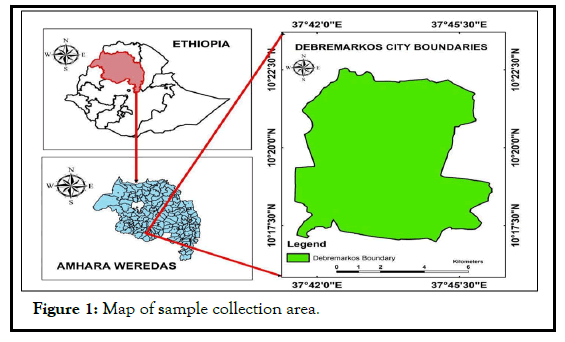

The study sample was taken from Debremarkos in the Amhara region, which is located 300 km northwest of Addis Ababa. The study area has a latitude and longitude of 10° 17′30"-10°22′30"N and 37° 42′ 0"-37°45′0"E respectively, with elevations ranging from 1283 to 2500 meters above sea level (Figure 1). The average temperature is 16.1°C, with minimum and maximum ranging from 9.7°C to 22.5°C [5].

Figure 1: Map of sample collection area.

Sample collection technique

The samples were collected from a five year old managed stand of Acacia deccurens in the Amhara forest enterprise, Debremarkos area. For sample tree selection, two plots with a size of 10 m × 10 m and a spacing distance of 20 m between the plots were laid down. Trees with merchantable log size, good morphological quality, a straight trunk, and no disease or pest symptoms were marked with numbers in each of the two plots. Thereafter, three trees were randomly selected from the tagged trees found in each plot. Totally, six trees were selected from the two plots according to the ASTM D143-83 standard. For the study, one disc was taken from each of the selected trees at the bottom (10%), middle (50%), and top (90%), for a total of 18 discs. Each disc was immediately clearly labeled and put into plastic bags in order to avoid moisture loss. Finally, all discs were taken to the laboratory of the forest products innovation center for further processing [6].

Sample preparation

The collected discs from bottom, middle and top parts were further transversally marked for the investigation of fiber properties, as shown on Figure 1 and sample specimens were taken at the discs near pith (10%), middle (50%) and near bark (90%) radii [7].

For the fiber dimension (length and width), matchstick sizes of (1 cm × 0.2 cm × 0.2 cm) were taken from pith to periphery, and 50% nitric acid was used for maceration because of its shorter reaction time and its being more economical when compared to other methods. Matchstick size samples were taken and immersed completely in a nitric acid solution, and kept in a water bath at 70°C for 5 to 6 hours, until the fiber was separated. The nitric acid was drained after cooling, and the macerated fibers were washed with distilled water and filtered through what man grade 1 filter paper with the fibers remaining on the paper. Two microscopic slides were prepared per sample, and images were taken using a camera attached Motic BA210 microscope. Then the dimensions of 50 fibers were measured using the Motic software [8].

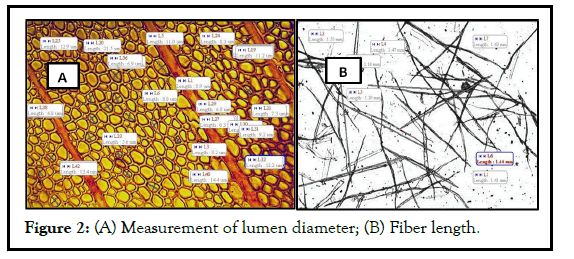

For cell diameter, lumen diameter, and cell wall thickness measurement, the specimens were softened in warm water below 100°C for one hour, and microtome slices were cut by using a Leica sliding microtome with a thickness of 20 μm. Then the slice was immersed in safranin solution and 25%, 50%, 75%, 90%, and 97% of alcohol concentrations, respectively, for one minute so as to remove excess safranin solution that may cause the invisibility of cells. Finally, the specimens were immersed in xylene for 1 minute and put on the slide (standard 7.5 cm × 2.5 cm). A small amount of Canada balsam was dropped on the slide, which was then covered with the slide cover and allowed to dry (Figure 2) [9].

Figure 2: (A) Measurement of lumen diameter; (B) Fiber length.

Thereafter, an image was taken with a camera attached Motic BA210 microscope, and 30 cells were sampled from each of the three transversal locations of pith to sapwood, for which cell diameter, lumen diameters, and cell wall thickness were measured using the Motic software as described by Ishiguri, et al., (Figure 2). The equations used for the computation of the derived values: Runkel ratio, slenderness ratio, flexibility coefficient, and wall coverage ratio were expressed in equations 1-4.

Runkle ratio=2X Cell wall thickness/Fiber lumen diameter (1)

Slenderness ratio =Fiber length/Fiber diameter (2)

Flexibility coefficient=(Fiber lumen diameter × 100)/Fiber diameter (3)

Wall coverage ratio=2X Fiber wall thicknes/Fiber diameter (4)

Statistical analysis

Statistical Package for the Social Sciences (SPSS) version 20 was used to analyze the data using descriptive statistics and an Analysis of Variance (ANOVA) procedure. Duncan’s Multiple Range Test (DMRT) was used to compare the mean values of each of the fiber dimensions and derived fiber values along the tree height levels and transversally from pith to sapwood [10].

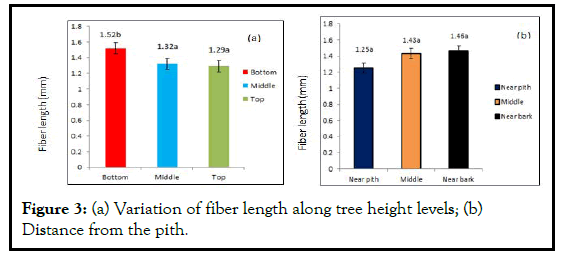

Fiber length along tree height and from pith to periphery

This study showed that fiber length ranged from 1.29 ± 0.14 mm to 1.52 ± 0.17 mm along with tree height and 1.25 ± 0.19 to 1.46 ± 0.11 mm from the pith to the periphery of the disks of A. deccurens wood. It varied significantly with tree heights (Figure 3). However, no significant difference (p<0.05) was obtained while going from pith to the periphery (Figure 4). Fiber length decreased from the bottom to the top; however, it increased from the pith to the periphery. The general decrease in fiber length from the bottom to the top and its corresponding increase from near the pith to the periphery, which was observed in this study, agrees with the earlier report of Tavares, et al., on A. melanoxylon wood [11].

Figure 3: (a) Variation of fiber length along tree height levels; (b) Distance from the pith.

Note: Mean with different letter are significant (p<0.05).

The mean value in fiber length obtained in this study (1.38 mm) is higher than the previous report of Tavares, et al., which ranged from 0.91 mm to 0.97 mm along the tree height and 0.75 mm to 1.06 mm from the pith to the periphery of A. melanoxylon. Additionally, the result was higher than the report of Santos et al., which ranged from 0.63 mm to 0.66 mm. The difference may be due to species, location and age. Moreover, the results were higher than those of other acacia species, namely Acacia mangium, which ranged from 0.96 mm to 1.20 mm, and Acacia bilimekii (1.016 mm-1.201 mm) [12].

The results obtained in this study were higher than pulpwood species such as Gmelina arborea (1.03 mm), Leucaena leucocephala (1.01 mm), and Eucalyptus species (0.67 mm–1.06 mm). Since the fiber length obtained is higher than that of other pulpwood species, the studied species is better suited for pulp and paper making. The decreasing trend of fiber length from bottom to top observed in this study could be due to the fact that minimal net photosynthetic activities for cell development at the top are caused by competition for leaf and branch development that may have led to better cell production at the bottom [13].While the increase in fiber length from pith to periphery could be due to an increase in the length of cambial initials with increasing cambial age and crown formation. Furthermore, this may be due to many molecular and physiological changes that normally occur in the vascular cambium during the aging process. The cells produced in the primary xylem divide less frequently, thus allowing more time for the fusiform initial section to elongate longitudinally and transversely. Fiber length is an important fiber parameter that affects pulp quality and paper strength and paper sheet formation and uniformity. It has also a strong effect on pulp yield, freeness, active alkali consumption, tear index, and bending stiffness [14].

Fiber width, lumen diameter, and cell wall thickness

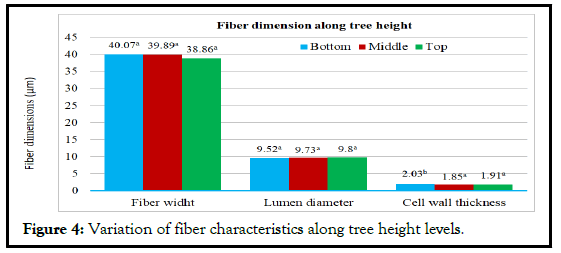

Variation along tree height levels: The result obtained in fiber width, lumen diameter, and cell wall thickness along the tree height of A. deccurens is presented in Fig 3. Along with the tree height, the fiber width ranged from 38.86 μm to 40.07 μm. Duncan multiple range tests showed that variation in fiber width was insignificant along height levels (p<0.05) and it decreased from the bottom to the top of the trees. The mean fiber width obtained in this study (39.60 μm) was higher than other acacia species previously reported by Santos, et al., (19.55 μm) and Santos, et al., (17.6 μm) on Acacia melanoxylon. The result is also higher than pulpwood species such as E. globulus. Accordingly, Santos et al., observed values ranging from 18.3 μm to 19.3 μm, and Miranda, et al., reported 14.5 μm to 22.2 μm of fiber width [15].

Similar to the fiber length, the decreasing trend of fiber width from base to top observed in this study could be due to the fact that minimal net photosynthetic activities for cell development at the top are caused by competition for leaf and branch development that may have led to better cell production at the base [16].

A. deccurens lumen diameter ranged from 9.52 μm to 9.80 μm along the tree height. A Duncan multiple range test revealed that the variations in lumen diameter along the tree heights were insignificant (p<0.05) (Figure 4). It increased from the bottom to the top of the trees. Lumen diameter has an effect on the pulping process. For instance, a larger lumen diameter gives better pulp beating because of the penetration of liquid into the void spaces of the fibers [17].

Figure 4: Variation of fiber characteristics along tree height levels.

Note: Mean of the same fiber dimension with different letter are significantly different (p<0.05).

Along tree heights, cell wall thickness ranged from 1.85 μm to 2.03 μm. Cell wall thickness of the three sections of the trees along their height significantly (p<0.05) differed between the bottom, middle, and top. It decreased from bottom to top of tree portions. The result obtained was lower than other pulpwood species. For instance, in E. globulus, it ranged from 5.4 μm to 7.3 μm along the tree heights, with a decreasing trend from the bottom to the top [18].

Wood with thick cell walls tends to produce paper with a poor printing surface and poor burst strength. Thick walled cells do not bend easily and do not collapse upon pulping, which inhibits chemical bonding. However, thin walled cells collapse upon pulping, bond well together chemically, and produce a smoother paper surface. Therefore, A. decurence is better than E. globulus for pulping in terms of its cell wall thickness [19].

Variation across from pith to periphery

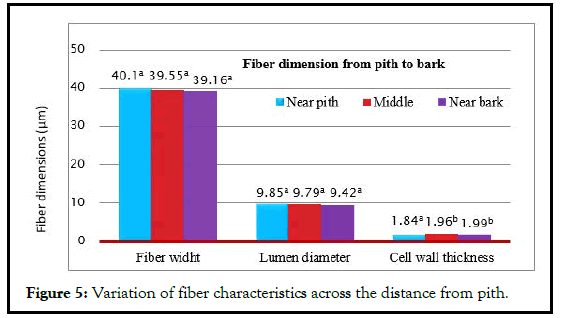

The fiber dimensions of A. deccurens wood at different distances from the pith to the bark are presented in Figure 5. Fiber width ranged from 39.16 μm to 40.10 μm from pith to bark. Duncan multiple range tests showed the difference between the fiber width near the pith and near the bark to be insignificant (p<0.05). The fiber width increased from the pith to the periphery. A similar trend was reported on Teak and on T. scleroxylon. The reason for this trend was attributed to the influence of cambium age on the development and maturation of fiber from pith to bark.

The mean lumen diameter of A. deccurens ranged from 9.42 μm to 9.85 μm while going transversally from the pith to the periphery. The lumen diameter at the pith was found to be less than at the periphery, though the difference was insignificant (p<0.05).

The cell wall thickness ranged from 1.84 μm to 1.99 μm transversally from the pith to the periphery. The difference between the cell wall thickness at the middle and near the periphery was found to be insignificant (p<0.05); however, both sections significantly (p<0.05) differed from the near pith on cell wall thickness. Cell wall thickness increased from near the pith to the periphery of the disk. The increase of cell wall thickness from the pith to the periphery of A. deccurens was previously reported on A. melanoxylon wood [20].

Figure 5: Variation of fiber characteristics across the distance from pith.

Note: Mean of the same fiber dimension with different superscript are significantly different (p<0.05).

The result obtained for the cell wall thickness was lower than Acacia melanoxylon, which ranged from 3.45 μm to 3.89 μm, and Eucalyptus species (3.29 μm to 3.86 μm) which are mostly used as raw materials for pulp and paper.

However, similar to the results of Jorge and Santos, et al., which ranged from 1.8 μm to 2.5 μm and 2.00 μm and 2.40 μm respectively. However, the result was less than A. cochliacantha which increased 5 μm to 7 μm from pith to bark. This difference may be due to species, age and growing environment differences in the sample trees, which significantly affect wood fiber properties (Table 1).

| Source of variation | df | Fiber length | Cell wall thickness | Fiber width | Lumen diameter |

|---|---|---|---|---|---|

| Position | 2 | 0.000* | 0.004* | 0.125ns | 0.69ns |

| Section | 2 | 0.000* | 0.021* | 0.849ns | 0.418ns |

| Position*section | 4 | 0.334ns | 0.385* | 0.959ns | 0.629ns |

| Residual | 45 | ||||

| Total | 54 |

*significant; ns: non significant

Table 1: Analysis of variance for fiber properties of Acacia decurrence.

Derived fiber values

In addition to the absolute fiber dimensions (fiber length, fiber width, lumen diameter, and cell wall thickness),fiber derived indices such as runkel ratio, slenderness ratio, wall coverage ratio and flexibility coefficient, help derive better judgement about the suitability of wood for pulp and paper making.

Variation of derived fiber values along tree height

Based on Table 2, the mean values of the runkle ratio ranged from 0.38 ± 0.04 to 0.42 ± 0.04. Duncan multiple range tests showed that there is no significant (p<0.05) difference in runkle ratio between the middle and top tree portions, however, both portions significantly (p<0.05) differed from the bottom portion (Table 2).

| Derived fiber values | N | Sampling height (%) | ||

|---|---|---|---|---|

| Bottom (10%) | Middle (50%) | Top (90%) | ||

| Runkle ratio | 18 | 0.42 ± 0.04b | 0.38 ± 0.04a | 0.39 ± 0.06a |

| Slenderness ratio | 18 | 38.67 ± 4.83b | 33.75 ± 7.15a | 33.72 ± 5.48a |

| Flexibility coefficient | 18 | 24.31 ± 4.02a | 24.59 ± 2.50a | 25.56 ± 4.06a |

| Wall coverage ratio | 18 | 0.10 ± 0.01a | 0.09 ± 0.01a | 0.10 ± 0.01a |

Note: Mean of the same row with different superscript are significantly different (p<0.05).

Table 2: Mean and standard deviation of derived fiber values along the height.

The mean values of slenderness ratio obtained along tree height levels ranged from 33.75 to 38.67. It has higher in bottom (38.67 ± 4.83) and minimum at the top portion (33.72 ± 5.48). Duncan multiple range tests showed that there was no significant (p<0.05) difference in slenderness ratio between the middle and top tree portions; however, both portions significantly (p<0.05) differed from the bottom portion. The slenderness ratio is related to fibre length and width and influences paper sheet density and increases tearing resistance.

The mean values of the flexibility coefficient along tree height levels of A. decurence ranged from 24.31 ± 4.02 to 24.59 ± 2.50 and it increased from the bottom to the top of the tree height. The flexibility coefficient did not differ significantly along tree height.

The mean values obtained for the wall coverage ratio along tree height ranged from 0.09 ± 0.01 to 0.10 ± 0.01. Duncan multiple range tests showed that there was no significant (p<0.05) difference in wall coverage ratio between the portions. Wall coverage ratio is an index for bending resistance and is related to fiber flexibility. Generally, all derived fiber values decreased from the bottom to the top of tree portions, except for flexibility and wall coverage ratio.

Variation of derived fiber values from pith to periphery

The mean values of the runkle ratio ranged from 0.37 to 0.42 transversally from the pith to the periphery of the disk. The runkle ratio significantly differed between the near pith and near bark positions; However, both the near pith and near periphery positions showed no significant difference from the middle (p<0.05).

This value agrees with the one previously reported by different scholars on A. melanoxylon. Furthermore, the values were lower than E. globulus wood, which is the most well-known pulpwood, and its runkle value was 0.56.

According to Kiaei, et al., runkel ratio is a parameter used to determine the suitability of a raw material for pulp. Runkel ratio was significantly related to pulp yield (positively) and digestibility (negatively). If the Runkle ratio<1, the fibre is highly appropriate for pulp and paper production; from 1 to 2 is regular; and above 2, it may not be used for paper. All runkle ratio values obtained in this study along with tree height and distance from pith were lower than 1, suggesting a good potential for pulp and paper production.

Based on Table 2, the mean values obtained in slenderness ratio from pith to periphery ranged from (31.51 ± 5.44 to 37.83 ± 5.66) with an increasing trend from inner to outer wood. The slenderness ratio significantly (p<0.05) varied between the near pith and the near bark; however, both sections showed no significant difference from the middle one (p<0.05). Fiber with more than 33 of slenderness ratio to be appropriate for use as raw material in pulp and paper industry. Hence, in terms of its slenderness ratio, A. deccurens was found to be suitable for pulp and paper production since the value obtained is more than the accepted standard (33%), both along tree height and from the pith to periphery of the disk. Pulp tear resistance increases with increasing fiber slenderness.

This means paper made from A. deccurens would have low tear strength and, therefore, may be suitable for wrapping and packaging purposes (Table 3).

| Derived fiber values | N | Distance from the pith (%) | ||

|---|---|---|---|---|

| Near pith (10%) | Middle (50%) | Near bark (90%) | ||

| Runkle ratio | 18 | 0.37 ± 0.04a | 0.40 ± 0.06ab | 0.42 ± 0.04b |

| Slenderness ratio | 18 | 31.51 ± 5.44a | 36.80 ± 5.98b | 37.83 ± 5.66b |

| Flexibility coefficient | 18 | 24.84 ± 3.08a | 25.25 ± 3.80a | 24.36 ± 3.93a |

| Wall coverage ratio | 18 | 0.09 ± 0.01a | 0.10 ± 0.02a | 0.10 ± 0.01a |

Note: Mean of the same row with different superscript are significantly different (p<0.05).

Table 3: Mean and standard deviation of derived fiber values across distance from the pith.

The value obtained for the flexibility index ranged from 24.36 to 25.25 transversally from the pith to the periphery and it was higher at the middle section (25.25 ± 3.80) of the disk. A Duncan multiple range test showed that there was no significant (p<0.05) difference in flexibility coefficient from near the pith to the periphery of the disk.

The overall mean value obtained for flexibility coefficient was less than previous work by Santos, et al., on A. melanoxylon wood which was in the ranges of elastic fiber (50-75%). Additionally, the value is less than other known pulpwood. For instance, E. globulus species (72%) and E. camaldulensis (70%).

Flexibility Coefficient (FC) can be divided into four classes: high elastic fibers with FC over 75; elastic fibers with FC between 50 and 75; rigid fibers with FC between 30 and 50; and highly rigid fibers with FC less than 30.

Furthermore, the values of the flexibility index ranged from 50% to 75%, which is suitable to produce good paper with high strength properties. According to this classification, the flexibility coefficient of A. deccurens fibers is 24.81, so it belongs to the highly rigid fibers group and does not satisfy the requirement for pulp and paper production.

The mean values obtained in the wall coverage ratio of A. deccurens from the pith to the periphery ranged from 0.09 to 0.10, and it was lower near the bark (0.10 ± 0.01). A Duncan multiple range test shows that there was no significant difference between near pith and periphery positions (p<0.05). A material with a wall coverage ratio value of less than 0.4 is considered to be good pulpwood. Therefore, A. deccurens is suitable for pulp and paper production since the value obtained meets the accepted standard (Table 4).

| Source of variation | df | Runkle ratio | Slenderness ratio | Flexibility coefficient | Wall coverage ratio |

|---|---|---|---|---|---|

| Position | 2 | 0.591ns | 0.01* | 0.017* | 0.222ns |

| Section | 2 | 0.01* | 0.002* | 0.785ns | 0.172ns |

| Position*section | 4 | 0.254ns | 0528ns | 0.993ns | 0.703ns |

*significant; ns: non-significant

Table 4: Analysis of variance for derived fiber values of A.decurence.

The fiber characteristics of the wood of A. deccurens trees growing around the Debremarkos area in Ethiopia were investigated to determine the usefulness of this tree as a fiber resource for pulp and paper production. All fiber dimensions decreased from the bottom to the top portion; however, they increased transversally from the pith to the periphery. Derived fiber values increased transversally from the pith to the periphery and decreased from the bottom to the top. A. deccurens with the exception of the flexibility coefficient, met the requirements of derived fiber values for pulp and paper production, and any part of the tree portion may be utilized along tree heights and transversally from pith to periphery. Compared to the wood properties related to pulp and paper quality of other Acacia and Eucalyptus species currently used for commercial pulpwood, this species showed similar properties. Generally, A. deccurens has good fiber properties (adequate fiber dimensions and its derived fiber values) as a raw material for the pulp and paper industry, except the flexibility coefficient, which was lower than the accepted standard.

• Based on the findings of the study, the following points are recommended: Since information on the fiber characteristics of A. deccurens grown in the studied area showed its suitability for pulp and paper production, attention should be given by tree growers, investors, the government, and non-governmental organizations to its expanded plantation in other parts of the country.

• In addition to the information on fiber characteristics revealed in this

study, production and testing of its pulp and paper should be done to

avail comprehensive information regarding its suitability.

• Since the studied species grows quickly and adapts to various agroecological

zones in Ethiopia, the government may consider it a

promising and alternative species for pulp and paper production in the

future.

• In Ethiopia, raw material evaluation and testing of pulp and paper

properties are lacking in addition to the country being dependent on

the import of pulp and pulp products. Therefore, the government, nongovernmental

organizations, research institutes, and higher learning

institutions should give special attention to this area.

The authors acknowledge all the coordinators, researchers, technical, and supporting staff members (finance, human resources and vehicles administration) of the forest products innovation center, of the Ethiopian forest development, for their overall technical, administrative, and logistical support during the research period. Additionally, thanks go to Amhara forest enterprise and local communities for letting us collect the samples for this study.

The authors have not declared any conflict of interests.

[Google Scholar] [PubMed]

Citation: Abara L, Gebeyehu D. Suitability of Acacia decurrence fiber morphology for pulp and paper making in Ethiopia. AGBIR 2024;40(3):1164-1169

Received: 31-Jan-2023, Manuscript No. AGBIR-23-88311; , Pre QC No. AGBIR-23-88311 (PQ); Editor assigned: 02-Feb-2023, Pre QC No. AGBIR-23-88311 (PQ); Reviewed: 16-Feb-2023, QC No. AGBIR-23-88311; Revised: 19-Apr-2023, Manuscript No. AGBIR-23-88311 (R); Published: 26-Apr-2024, DOI: 10.35248/0970-1907.24.40.1164-1169